Since 1990 – with a focus that verges

on obsession – Danum Industrial Ltd. (DI) has delivered

digital radiography devices, software, peripherals, solutions and associated

services

to the medical and industrial imaging

sectors.

In 2022 DI specialised exclusively in

Non-Destructive Testing (NDT)

In all that we do we strive to uphold

four core ideals

First Class Service

Premium Quality

Optimum Performance

Unbeatable Value

We know

Our products must be innovative and

appropriate

Our services must be responsive and

timely

Our pricing must be competitive

Whether you are an end-user, a

services provider or a re-seller of the equipment

first of all we listen

Only when we are sure we can serve you in the right way to suit the specifics

of your individual situation

do we offer to supply to you the

right product and associated services at the right price.

We invite you to scan through the

pages of this website

to find out more about what we do and

how we do it.

We understand that your requirements

will be unique and varied,

so we look forward to hearing from

you soon

to discover together how exactly we can serve you

We thank you for your interest and do hope we

can be of service

Recognising that NDT

will - like the rest of industry - soon be completely transformed by digital

technologies

Danum Industrial has

made the strategic decision to specialise in supply of digital NDE for the NDT radiography

industry.

This includes

advanced image capture devices, handling equipments, complementary products and

peripherals.

All hardware is configured and integrated for systems operation, visualisation

and archiving with i-Rad software.

Devices are frequently combined with software and IT systems to deliver a

complete bespoke solution.

Because of the limitations of the

website this is just outline information.

Please contact us for full details.

please click on the heading

Hardware

Danum Industrial can

supply a range of over 80 flat panel detectors for almost any conceivable NDT

requirement.

Clearly this is too many to illustrate on a rationalised website.

Company sales

consultants discuss a customer’s individual needs to ensure supply of the most

appropriate solution.

Please contact us

to advise your specific requirements.

Following is a

selection of three of the most commonly specified models and the new bendable

FPD.

Please click on this section heading

for more FPD products and details on the next page

Model No

FPD

2430H D1

Panel

Technology: a-Si - CsI / Gadox

Usage: static

Active

Area: 291×233 mm

Ext

Dim: 380×380×19 mm

Pixel

Pitch: 76㎛ (or “binning” 152 μm)

Pixel

Matrix: 3840 × 3072

Energy

Range: to 450 kVp

AD

Conversion: 16

bit

Water & Dust Proof.

IP

Rate: IP67

X-ray

Interface: Software TRG, AED

Weight

3.9 kg

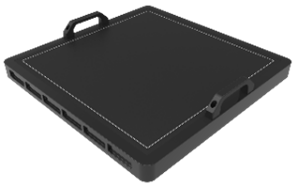

Model No

FPD 4343N V1

Panel

Technology: a-Si - CsI / Gadox

Usage: dynamic

Active

Area: 432 × 432 mm + handles 40 mm

Ext

Dim: 500 × 500 mm

Pixel

Pitch: 150 ㎛

Pixel

Matrix: 2880 × 2880

Energy

Range: 20-450 kVp

AD

Conversion: 16 bit

Frame

Rate: 15 fps (1×1), 30 fps (2×2)

Data

Interface: GigE Vision

Weight: 29 kg

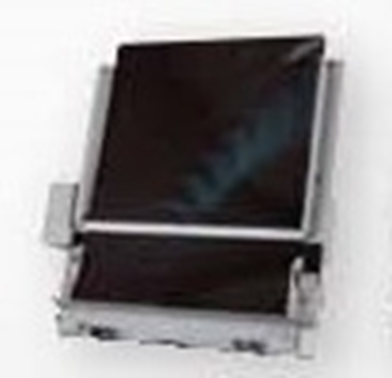

Model No

FPD 4336i D1

Panel

Technology: a-Si - CsI / Gadox

Usage: static / dynamic - wireless

Active

Area: 426 × 350 mm

Ext

Dim: 460 × 384 mm

Pixel

Pitch: 100 ㎛

Pixel

Matrix: 4288 × 3524

Energy

Range: 20-225 kVp

AD

Conversion: 16 bit

Frame

Rate: 3.5 fps (1×1), 7.0

fps (2×2)

Data

Interface: GigE Vision

Wireless

i/f WIFI (802.11 n) 2×2

MIMO

Weight: 4.3 kg

Model No

FPD 1036FW D1

FPD with curved surface without distortion

Usage:

static

Panel

Technology: a-Si

Scintillator: CsI

Active

Area: 107 × 322 mm

Curve

Diam: 8”–42” (203-1067 mm)

Pixel

Pitch: 140 ㎛

Pixel

Matrix: 768 × 2304

Energy

Range: up to 225 kVp

AD

Conversion: 16 bit

Water & Dust Proof IP

Rate: IP67

Wireless

Interface: WiFi

(802.11n) 2×2 MIMO (also Wired)

X-ray

Interface: Software TRG AED

Weight:

2.4 kg

Danum Industrial has great experience

in the supply of film digitizers and computed radiography systems.

The Company knows that some 99% of industrial radiography is still performed

using analogue devices and techniques.

Clearly there is an incalculable

number of X-rays that cannot be ignored and must be integrated into the digital

world.

The bridging technology to make a

seamless transition is a film digitizer operating with a viewing/archiving

application.

DI offer two outstanding technologies

to meet every need for film digitization, Charge Coupled Device (CCD) and

Laser.

Combined with our powerful device

operation, viewing and archiving software the transformation is complete

Please click on this section heading

for more details on the next page .

Model No

SCC 35 M1

Hi Density CCD Technology

Up to 1200 dpi = 21 µm

8/16-bit - 0.37-4.5 OD

Max scanning size 14” × 200”

Supports DCM, BMP, JPEG, TIFF

Lossless & Lossy JPEG Compression

Auto Film Feed Options (left & right)

18

Model No

SCL 35 A1

Hi Density Laser Technology

50-500 µm - 8/12-bit - 0.03-4.7 OD

Scanning size: W 10-35 × L 19-500 cm

Supports: DCM, BMP, JPEG, TIFF

100-sheet Auto Film Feed Option (see right)

Danum Industrial can

supply one of the most advance technologies for in-motion scanning in the field

of NDT.

We are proud to

offer the Time-Delay Integration (TDI) Camera

Simply put TDI is a

scanning device with frame transfer to produce a continuous video image of a

moving object.

Achieved by means of

a stack of linear arrays aligned with and synchronized to the motion of the

object to be imaged

as the image moves from one line to the next,

the integrated charge moves along with it.

This provides a higher resolution at lower

light levels than is possible with a line-scan camera.

Please click on this section heading

for more details on the next page

Application: Ultra high-speed

inspection line

Speed: Configurable - to max 144 m/minute

Width: Up to a maximum of 293 mm

Scanning: Bi-directional (improves

large object cycle time)

Resolution: 48 µ

Bit depth: 12 or 16 bit

- even in dark samples by using 150 line integration

X-ray exposure: 10-180 kVp

X-ray sensitive area: 221.1 × 293.4 mm (h) / 7.2 mm

Danum Industrial know objects and

structures in the NDT world come in many shapes, sizes, materials and weights.

Positioning objects precisely, firmly

and safely for a perfect shot is an essential part of successful NDT

inspection.

With its partners DI has developed a purpose-designed range of handling systems

for use in digital NDT.

Whether your application is for

fixed, dynamic or rotating image capture we can help.

Please click on this section heading

for more details on the next page

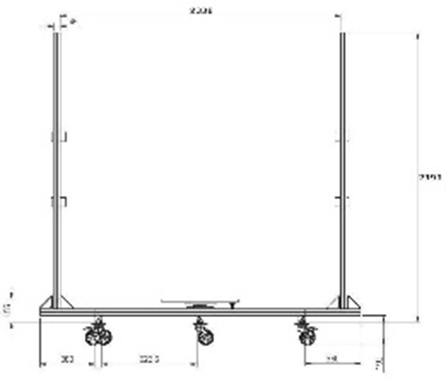

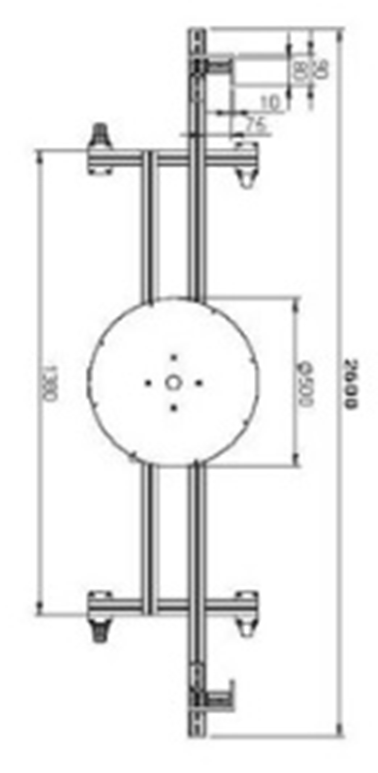

Rotating Table

Dynamic

Model No

PDR 500 C1

Motorized - 360º rotary system

350-1000 mm diameter

automatic cylindrical scanning

on own-axis of object /

on R+Z polar coordinates of a plane and at

different heights

fully integrated in i-Rad software

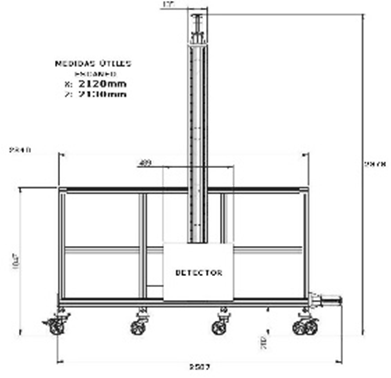

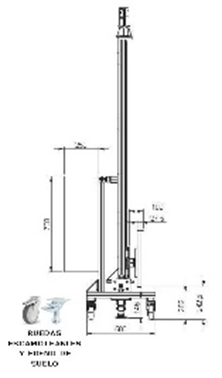

Lateral

Positioner

Dynamic

Model No

PDL 2100 XY

i-Rad Application

Enables scanning in X-Y axes

select X-ray of part of a large

object

useful X-Y stroke 212 × 213 cm

payload 20.0 kg

configurable displacement speed

precision <10 µm

Volumetric

&

Flat

Positioner

Model No

PDV 2400 XY

Enables scanning in X-Y axes

to X-ray part of a flat or bulky object

multiple size objects

500 mm circular fixed platform

6 retractable braked blockable

castors

All DI digital NDT solutions

require a dedicated PC workstation for device operation, viewing, comms and

archiving.

DI sales consultants will

specify appropriate hardware to meet customer requirements for precision,

speed and capacity

We strongly recommend

supply of pre-loaded, configured and tested turn-key solutions for guaranteed

performance.

PC Workstation

Intel i7-6700 (or higher)

8GB RAM min

8GB VRAM min

HD: 512 GB SSD + 1TB SATA

DVD RW

Keyboard + Optical mouse

Microsoft W10 Professional

Monitors